Rolls and Shafts

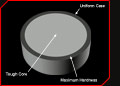

Flame-hardening is the best,

and sometimes the only, way to heat-treat large

and outsized rolls. Less distortion and higher surface

hardness, combined with ductility and core strength,

are the results of flame-hardening.

Our process is also capable

of selectively hardening varying diameters on the

roll body, bearing fits, along with

click image to enlarge

click image to enlarge |

the journals when required.

Flame-hardening of rolls provides

a better wear surface, uniform case, maximum hardness,

while leaving a both a tough and ductile core.

Gears

and Sprockets

Gears

and Sprockets

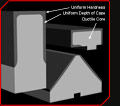

Gears, sprockets and gear

racks benefit the most from quality flame-hardening.

Replacement of worn gears can be expensive, time

consuming and difficult. Chicago Flame’s techniques

give you maximum durability for longer wear.

We can harden gears of any

size,

click image to enlarge

click image to enlarge |

whether cast or fabricated. Only the contact surfaces

of the teeth are treated, leaving the base metal

at its original strength.

Liners,

Machine Ways, and Rails

Liners,

Machine Ways, and Rails

Flame-hardening is the best

and quite often the only process for selective hardening

of large or unusual shaped liners, ways and rails.

Chicago Flame Hardening has a unique process on

this application.

click image to enlarge

click image to enlarge |

We suggest you contact our technical staff to discuss

parameters for straightening tolerances and grind

stock allowances prior to manufacture.